Liquids come into contact with solid surfaces in countless applications—from everyday situations like painting a wall or applying medicine, to critical industrial processes in electronics manufacturing and oil extraction. In each of these scenarios, understanding what happens at the liquid-solid interface can mean the difference between product success and failure.

Contact angle is the measurement that reveals this interaction. It quantifies how well a liquid spreads on or beads up against a solid surface, providing crucial insights into whether a coating will adhere properly, a medical device will function as intended, or an industrial process will yield the desired results. Knowing the contact angle value gives a strong indication of the performance of your product and the likelihood of process success.

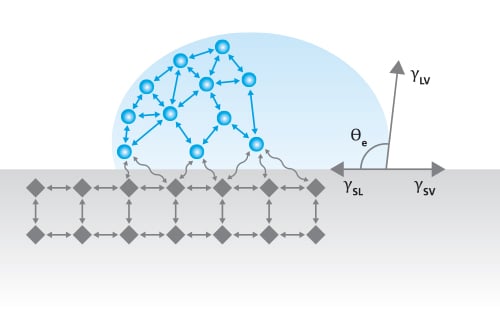

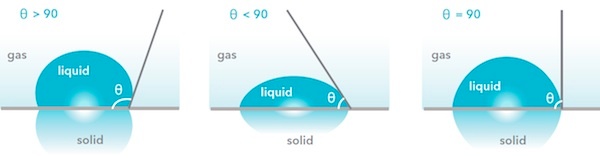

Contact angle is the angle that forms where a liquid droplet meets a solid surface. Measured in degrees, it tells you whether the liquid will spread across the surface or bead up and pull away—based on the balance between the liquid's internal forces and its attraction to the surface.

Contact angle is the foundation for understanding wettability—the preference of a liquid to maintain contact with a solid surface. When using water as the measuring liquid, the contact angle with value directly determines whether a surface is classified as hydrophobic, hydrophilic, or something in between.

Hydrophilic surfaces (water-loving) have a contact angle below 90 degrees. Water spreads easily across these surfaces, creating a small contact angle. This is what you want when applying coatings or adhesives, as good spreading facilitates better adhesion and performance.

Hydrophobic surfaces (water-repelling) have a contact angle above 90 degrees. Water beads up and pulls away from the surface, minimizing contact area. While sometimes undesirable, hydrophobic properties are intentionally engineered for applications like water-resistant textiles or anti-corrosion coatings on cars.

At the extremes, you have complete wetting (contact angle near 0°), where liquid spreads completely across the surface, and superhydrophobic surfaces (contact angle above 150°), where water forms nearly perfect spheres and rolls off. Each classification has specific applications and requirements.

In PCB manufacturing, HMDS treatment improves photoresist adhesion during lithography. Contact angle measurement quickly confirms the treatment succeeded, preventing costly patterning errors. Conformal coatings also require good wettability to ensure complete coverage, making contact angle essential for quality control.

Contact angle of ink on paper directly affects droplet spreading, absorption, image quality, and color saturation. Contact angle measurements help optimize paper and surface treatments for consistent, high-quality inkjet printing.

Wettability of biomaterials is critical for device biocompatibility. For example, hydrophilic coatings on urinary catheters improve lubricity and patient comfort. Specialized functional surfaces—such as self-cleaning, anti-icing, and blood-repellent coatings—rely on extreme wettability properties, making contact angle essential for performance verification.

Rock wettability directly affects oil recovery rates. Unconventional reservoirs are typically oil-wet, making extraction difficult. Wettability alteration—changing the surface from oil-wet to water-wet—is one of the most effective enhanced oil recovery methods. Contact angle measurements determine whether these strategies will succeed before full-scale implementation.

While contact angle provides valuable information about how liquids interact with surfaces, it offers an even more powerful insight when combined with surface free energy analysis.

Contact angle measurements alone tell you how a specific liquid (like water) behaves on a surface. However, surface free energy describes the inherent properties of the solid itself, making it possible to predict how any liquid will interact with that surface—regardless of which measurement liquid you used.

If you are interested in deeper surface characterization, our articles on exploring different surface free energy methods and how to measure surface free energy provide more comprehensive insights into material behavior.

Understanding contact angle is essential for predicting adhesion outcomes. What is required for good adhesion involves more than just material selection—it requires that the coating or adhesive can spread adequately on the substrate. Contact angle measurements serve as a predictive tool, helping you avoid adhesion problems before they affect your product.

In fact, poor contact angle (high angle, low wettability) is one of the primary reasons adhesion fails in manufacturing. By measuring contact angle early in development, you can identify and resolve surface preparation issues that would otherwise lead to costly field failures.

Related reading: How to solve adhesion issues with contact angle measurements?

A high contact angle means the liquid beads up and does not spread well on the surface. This indicates low wettability and a more hydrophobic surface.

A low contact angle means the liquid spreads easily across the surface. This indicates high wettability and a more hydrophilic surface, which is generally beneficial for coatings and adhesion.

Contact angle is quick to measure and provides immediate feedback on surface treatments, cleanliness, and coating performance. This makes it ideal for quality control in production environments.

Contact angle measurement is a simple yet powerful tool. Whether you're developing a new coating, validating a manufacturing process, ensuring biomedical device performance, or optimizing adhesion in assembly, contact angle provides the quantitative data you need to make confident decisions.

Biolin Scientific specializes in contact angle measurement instruments and systems designed for research, quality control, and production environments. Our solutions deliver fast, accurate, and reproducible contact angle data—from single-point measurements to comprehensive surface mapping across large substrates.

To read more about how contact angles are used across industries, please download the overview below.

Ready to optimize your surface characterization? Explore our contact angle measurement solutions to find the right instrument for your application, or contact our team to discuss your specific measurement needs.

Editors note: This blog post was originally published on October 30th 2018, and has since been updated for clarity and completeness.

Learn how to use contact angle measurements to evaluate surface cleanliness on different materials and link cleaning steps to reliable adhesion and coating quality.

Learn how wettability, surface free energy and surface roughness define paper and paperboard surface properties – and how to measure them for reliable print, coating and sealing performance.

Smart materials are materials that sense a change in their environment and respond in a useful, reversible way.

Discover how contact angle measurements help optimize plasma treatment for improved wettability and adhesion in industrial applications.

Discover why PFAS-free coatings are needed, the challenges they present, and key strategies for developing high-performance alternatives.

At the heart of droplet formation are two key molecular forces: cohesion and adhesion.

Contact angle measurements provide a golden standard for evaluation of surface properties for quality control.

Contact angle is the angle a droplet forms in contact with a solid surface. Thermodynamically, it is a balance between cohesive and adhesive forces.

Anna Junnila is Customer Care Manager at Biolin Scientific. She takes pride in making advanced technology accessible for every user and is committed to guiding customers through every stage of their research journey. She holds an MSc in Electronics and Electrical engineering from Aalto University.